Oxyver service can guarantee the quality and compliance of its treatments with customer specifications.

For this purpose, Oxyver has a well-equipped laboratory, in order to ensure the quality of the production in terms of thickness, technical and aesthetic characteristics and the control of chemical processes.

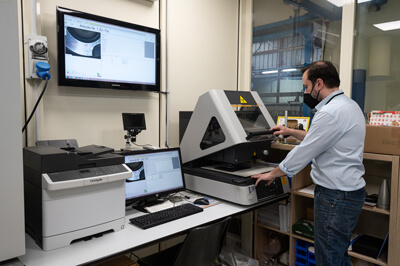

Some of the tools used

Energy dispersion X-ray fluorescence spectrometer for automated material analysis and non-destructive measurement of the coating thickness according to ISO 3497 and ASTM B 568 standards.

Programmable oven with ramps and FORCED VENTILATION RS 232 serial interface with 4 8-segments programmes of work, a capacity of 240 litres and a maximum achievable temperature of 300°C.

Metal analyzer with libs technology. It provides in one second results for all the most used alloys, including aluminum, magnesium, titanium, cobalt, chromium, nickel and copper alloys, stainless steels, tool steels, micro-alloyed steels and more.

Machinery used for the corrosion test on coated samples in order to predict their suitability for use.

Fischer portable instrument with interchangeable probes that allow non-destructive and highly precise measurements of the coatings.

It performs external and internal measurements, it takes depth measurements, steps measurements and differential measurements.

High precision instrument which measures the size of a target by tightening it with a micrometric screw.

Scientific instrument that allows to enlarge or produce images of small objects that would otherwise be impossible to be studied with the naked eye. It allows to observe the details through an indirect observation by photography and/or electronic systems.

Copyright© 2022 Oxyver Service s.r.l. VAT: 02463020590 | Privacy Policy